Introduction产品简介

3M清洗剂HFE-71DE是由HFE-7100(九氟丁基甲醚)和反式二氯乙烯组成的共沸物。HFE-71DE是真正的共沸物,气相和液相具有相同的成分组成。

HFE-71DE主要用于中等污物的清洗或者脱脂以及作为特殊溶剂使用。主要用于替代氟利昂对臭氧有破坏的物质。HFE-71DE安全暴露极限可以参考HFE-7100的750ppm暴露极限以及反式二氯乙烯的200ppm的暴露极限。

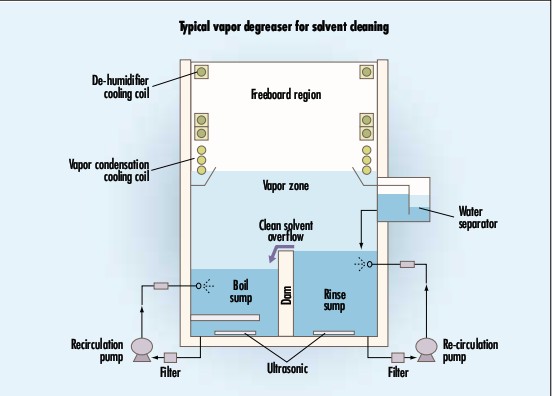

由于加了反式二氯乙烯,其溶解能力得到提高,而且HFE-71DE的表面张力很低,不燃,沸腾时成分稳定,所以HFE-71DE可以用于浸没或者气相清洗。HFE-71DE共沸物具有以上特点,也用途涂层和润滑油的溶剂。

3M Novec 71DE Engineered Fluid is a hydrofluoroether, Methyl Nonafluorobutyl Ether (C4F9OCH3), in an azeotrope formulation with trans-1,2-dichloroethylene (t-DCE). This

mixture is a true azeotrope, with constant vapor and liquid composition at its boiling point.

This fluid is ideal for medium-duty cleaning and degreasing tasks, as well as specialty solvent applications, and is intended to replace ozone-depleting materials in many applications. It has zero ozone depletion potential and other favorable environmental properties (see Table 2). Novec 71DE fluid has a time-weighted average exposure guideline of 750 ppm (eight hour average) for the 3M Novec 7100 Engineered Fluid component, and 200 ppm (eight hour average) for trans-1,2-dichloroethylene (t-DCE). These exposure guidelines suggest there is a large margin of safety for use of Novec 71DE fluid in its intended cleaning applications.

The increased solvency and low surface tension, nonflammability and constant composition during boiling of Novec 71DE fluid make it ideal for immersion and vapor degreasing applications. These properties also may make the azeotrope ideal for certain coating and lubricant deposition applications where increased solvency is required.

Typical Applications典型应用

Cleaning, rinsing and drying agent清洗、漂洗和干燥的溶剂

Cleaning of oils, greases, waxes

Specialty solvent applications, including coatings特殊溶剂

|

今天是:

今天是:

今天是:

今天是: